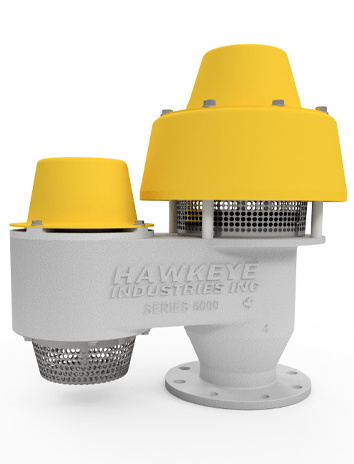

Pressure and Vacuum Relief Vent

SERIES 6000 PVRV

- Direct-acting pressure and vacuum relief vent (PVRV)

- Patent-pending Unidirectional Binary Relief (UBR) valve technology offers higher flow rates with less overpressure while offering flutter-free operation.

- Offered in multiple connection sizes with flexible pressure and vacuum relief settings in a wide array of pressure + vacuum and pipe-away configurations.

- Soft Viton gaskets to combat fugitive emissions, with four-point pallet guides for repeatable reseating, and bubble-tight sealing up to 90% of set pressure.

- Flow rates third-party verified.

- Made and stocked in Canada.

Direct Acting Pressure and Vacuum Relief Vent

- The Series 6000 is actuated by tank pressures and vacuums directly. No external instrumentation or controls are required.

- Relief values set via weights on valve pallets, and adjustable in 0.5 ozsi [0.22 kPa] increments.

UBR Valve

- A vent equipped with UBR valve technology is capable of higher relative relief flow rates at lower overpressures as compared to a conventional direct-acting valve.

- This allows the set pressure of the UBR valve-equipped vent to be much closer to the design pressure of the tank or process than a conventional direct-acting valve.

- Both the pressure and vacuum valves in the vent can be configured as Hawkeye’s patent-pending Unidirectional Binary Relief (UBR) valve or as a standard weight-loaded direct-acting valve.

Flexible Configuration

- The Series 6000 PVRV is available in 2, 3, 4, and 6” ANSI 150# connections.

- 8” API 12B/F (gauge hatch) connections are also available, sharing the flow characteristic of the 6” ANSI 150# device.

- The PVRV can be configured as an end-of-line vent, with pressure and vacuum relief to the atmosphere, or optionally as an in-line vent with pressure relief to an integral 6” ANSI 150# pipe-away connection.

- The device can be configured to provide both pressure and vacuum relief, pressure relief only, or vacuum relief only.

Composite FKM Gasket

- The composite gasket bonds sponge Viton™ (eFKM), to standard Viton™ (FKM) for durability.

- The soft eFKM conforms to the contoured seat to improve the seal while the standard FKM ensures the ruggedness and reliability of the gasket.

- Bubble-tight sealing to 90% of set pressure is achievable.

Precision Components

- Precision molded and machined sealing components provide consistent sealing and venting performance.

- Glass-filled Nylon pallets and seats provide excellent chemical, corrosion, temperature, and wear resistance while remaining light, strong, and extremely durable.

Full Encompassing Guide

- The full-encompassing pallet guide on the Series 6000 PVRV provides full confidence that the internal moving components will not become dislodged or misaligned.

- 4 point contact reduces friction, wear, and the risk of becoming stuck over a full contact guide.

Empirical Flow Characteristic Data

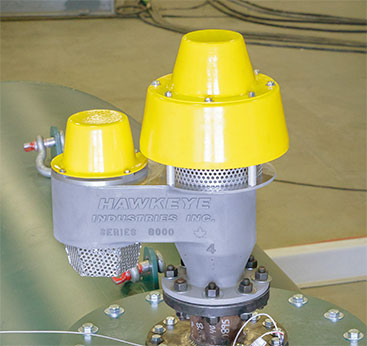

- Data used to determine the pressure and vacuum relief flow rates were generated from full-scale flow characteristic determination conducted on all vents in the summer of 2017.

- All data was collected and verified by C-FER Technologies (1999) Inc. in accordance with API 2000, 7th Ed. Full report available upon request.

ACI Compressors

Our line of natural gas compressors are built tough to withstand the harshest industrial conditions. Ideal for a wide range of applications such as vapor recovery, gas-lift, and land-fill gas, our compressors are designed to provide years of reliable service. Constructed from high-quality metals and components, ACI's gas compressors are engineered to perform their best in demanding oil & gas, industrial, and process environments. If you're looking for a durable, heavy-duty gas compressor that will get the job done right, look no further than ACI Compressors.

Need Sales Assistance?

Series 6000 PVRV mounted on flow test apparatus, June 2017. Photo courtesy C-FER Technologies (1999) Inc.

Booster Compressors. Vapor Recovery Units.

Ready for a more efficient operation? Contact us today to learn how ACI Compressors can help you with your next project.