Vapor Recovery Units & Towers

Vapor Recovery Units Standard Features

- Pressure piping and vessels built to code standards (code vessel available on request).

- Heavy-duty oilfield style skid base with environmental rail and dual drain points.

- An advanced industry-leading control system, with customizable options (SCADA capable).

- Pressure circuits are protected by normal shutdown settings and relief valves.

- Variable speed after-cooler/oil-cooler, for precise temperature control.

- Torquemaster TEFC electric driver, Baldor ABB option available.

- Rotorcomp oil-flooded rotary screw compressor module.

- C1D2 electric throttling recycles valve.

- Grundfos CRN -1 condensate pump, with high-pressure option.

- Common, non-proprietary, industry-accepted componentry.

- A normal, open skid layout allows easy maintenance access.

Standard Capacities

Flow volumes from ........................... 10-1100 MCFD

Standard unit sizes ..... 30, 60, 75, 100 , 125 and 200 HP

ACI Compressors

Our line of natural gas compressors are built tough to withstand the harshest industrial conditions. Ideal for a wide range of applications such as vapor recovery, gas-lift, and land-fill gas, our compressors are designed to provide years of reliable service. Constructed from high-quality metals and components, ACI's gas compressors are engineered to perform their best in demanding oil & gas, industrial, and process environments. If you're looking for a durable, heavy-duty gas compressor that will get the job done right, look no further than ACI Compressors.

Need Sales Assistance?

Booster Compressors. Vapor Recovery Units.

Ready for a more efficient operation? Contact us today to learn how ACI Compressors can help you with your next project.

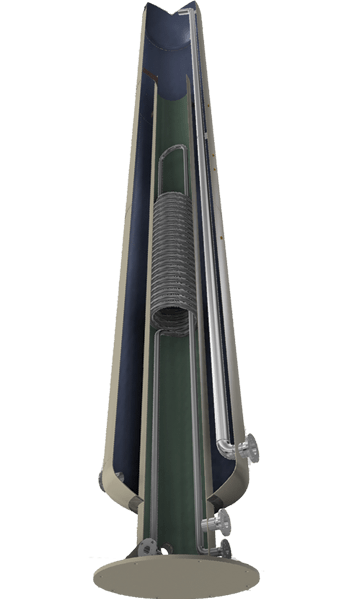

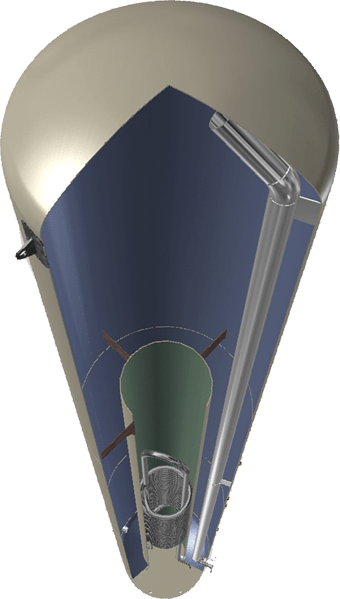

MAX Vapor Recovery Towers

Vapor Recovery Towers (VRT’s) are used to prevent oxygen in the flash gas stream. Standard VRT’s are less effective at removing all of the VOC’s from the product. Our Patented MAX VRT increases the flash rate of VOC’s within the tower.

How it Works

Increases product temperature by introducing (free) heat from the VRU compressor discharge, or other available sources, both gas and liquid. Reversal of product flow allows hydrostatic pressure to decrease during retention time instead of increase. Lighter constituent flash-off aerates and agitates the increasingly lighter liquid column as the product rises in the tower. The best chance for flash-off of heavier constituents is inside the tower, not in your tanks.

Benefits Over Standard Towers

- Increase of revenue from high BTU flash gas sales.

- Reduces RVP concerns with downstream purchasers.

- Easy rig-up due to multiple clocking positions on connections.

- Cost is competitive with Standard VRT’s, a higher potential for ROI.

- Reduces the size, or negates the need for further downstream control devices.

- Alleviates the requirement for a VRU aftercooler when discharge gas is used for heating.

- The design significantly reduces the chance of flooding the tower during production spikes.

- Installed riffle trays extend product retention time within the low-pressure gas cap area.

ACI Compressors

Ideal for a wide range of applications such as vapor recovery, gas-lift, and land-fill gas, our compressors are designed to provide years of reliable service. Constructed from high-quality metals and components, ACI's gas compressors are engineered to perform their best in demanding oil & gas, industrial, and process environments.

Need Sales Assistance?

Booster Compressors. Vapor Recovery Units.

Ready for a more efficient operation? Contact us today to learn how ACI Compressors can help you with your next project.